How Hash Is Made

Hash production combines age-old traditions with contemporary techniques, and we delved into the methods employed by Licensed Producers to reveal the secrets behind their unique hash-making processes.

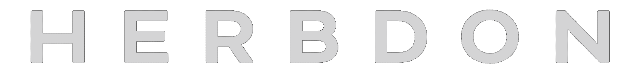

Hash roots trace back thousands of years. Derived from the resinous trichomes on the cannabis plant, hash is a concentrated cannabis product rich in cannabinoids and terpenes. To unveil the transformation of these trichomes into hash, here we provide insights into distinctive hash production methods.

Step 1: Selecting and Preparing the Flower

Before hash production begins, producers must make crucial decisions about the cannabis flower they will use. Whether sourcing whole plants from external growers or opting for trimming in-house dried flowers.

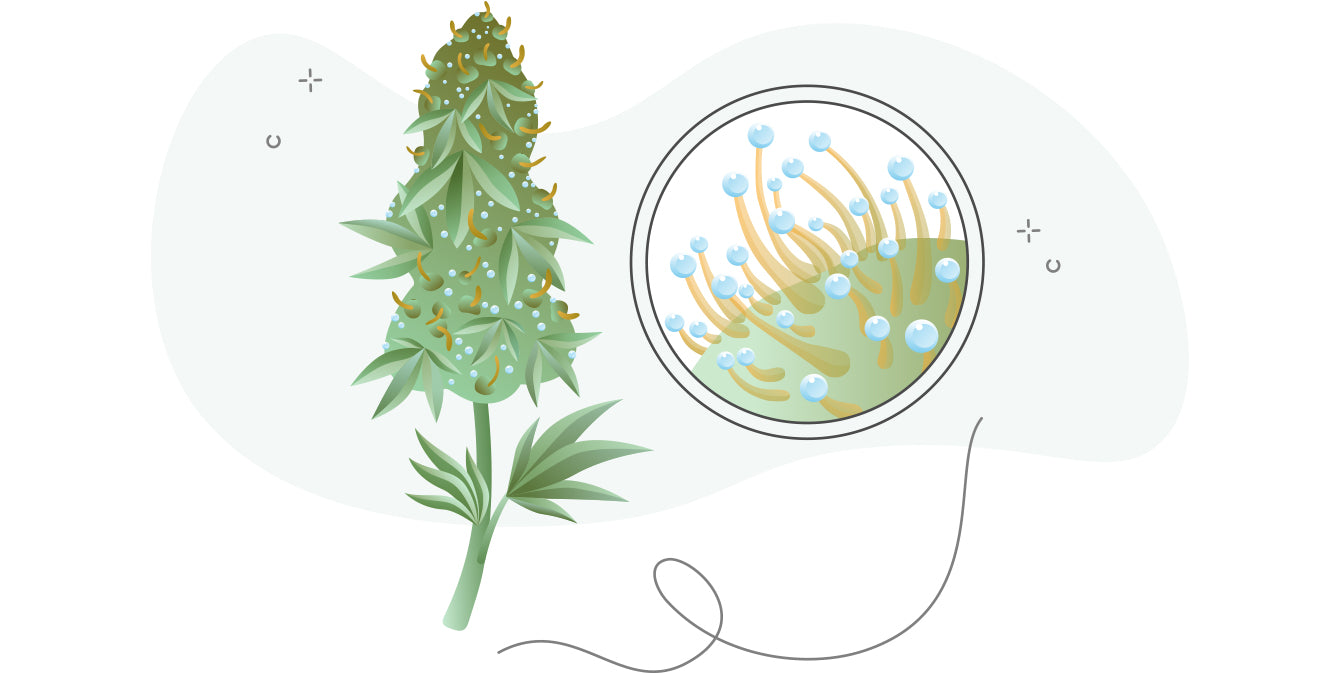

Freezing the flower is common to maintain freshness and preserve trichomes and terpenes. Some ensure flowers are frozen within 24 hours of harvest and spend at least 24 hours in a -40ºC freezer before hash processing.

Step 2: Collecting the Concentrate

Once the dried or fresh-frozen flower is ready, the trichomes are separated. There are different types of hash, with bubble hash and dry sift hash being among the most popular. Both are solvent-free and share similarities in the resulting product, but the processes are distinct.

-

Dry Sift Hash: Employing a variation of the dry sift process, involves a tumbling machine with screens sized for trichome glands. The plant material is brushed over screens, allowing separated trichomes to fall into a container below.

-

Bubble Hash: This method requires a more intricate process, involving agitating the flower in ice water to separate trichomes. Using a washing system, involves agitating the flower and allowing trichomes to settle and be drawn through a series of filters.

Both methods take hours to over a day to complete, resulting in a concentrated collection of trichomes with high cannabinoid and terpene levels, showcasing a light to dark golden hue.

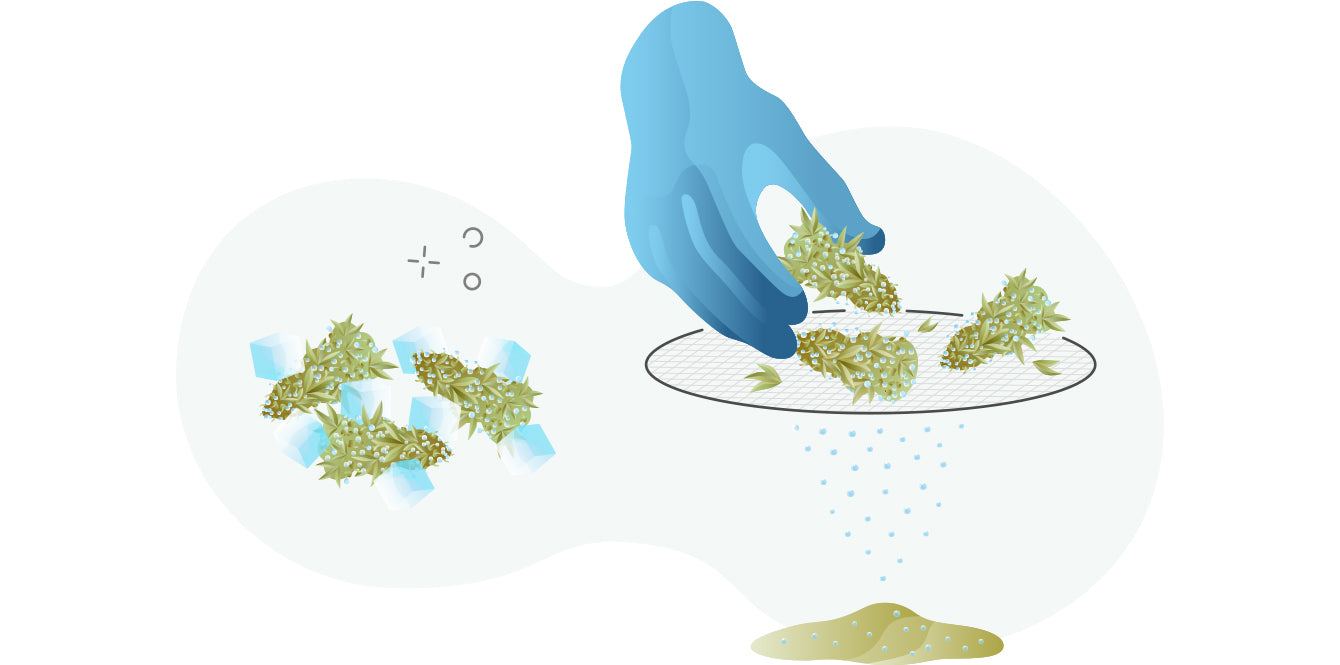

Step 3: Drying and Pressing

Depending on the extraction method, the concentrate may undergo drying before being transformed into hash. Quickly freeze-drying the concentrates allow the removal of moisture, preventing mould and preserving terpenes. Dry sift does not require additional drying.

Transforming the concentrate into hash involves heating and pressurising. A heated press can be used to mold the concentrate into portions, applying specific pressure and temperature. (Two to three pounds per inch (PSI) at 40ºC to 60ºC for four to 10 minutes.)

The resulting solid brick or ball of hash can be broken apart for use in various consumption methods.

Step 4: Testing and Packaging It Up